- Dimension: Package in crate 720*670*1170mm (29”x26”x47”); Unpacked machine 630*560*1075mm (24”x22”46”)

- Power supply: AC110V±10%~60Hz

- Compressor power: 3/8HP

- Patented SRR (Supreme Recovery Rate) system, guarantees over 99% recovery rate achieved in very short recovery time.

- Vacuum: pump capacity: 120L(32Gal)/min

- Evacuation time selection: 2-240min,

- Vacuum leak test time selection: 0-30min.

- Electronic oil injection: 3 separate vessels, 250ml capacity for PAG /POE/UV, high transparency

- Used oil vessel: 400ml capacity, high transparency

- Refrigerant charging speed: 1Kg/Min.

- High capacity spin on filter-dryer: 600ml capacity:

- Accuracy of refrigerant cylinder load cell: ±10g

- Accuracy of oil containers load cells: ±3g (For better oil injection accuracy, ±1g, please order optional function of individual load cell for each oil vessel)

- Refrigerant cylinder: 10KG, with heater.

- Machine maximum working pressure: 20bar.

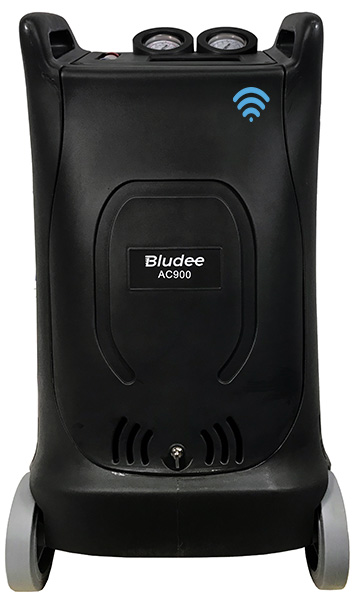

- Display: 7’’ touch screen, powered by android platform.

- Gauges: High side -1bar~30bar, Low side -1bar~16bar,

- Digitally displayed cylinder pressure and temperature

- Vehicle A/C database included, with additional user database input.

- Thermal printer

- Electronically controlled air purge.

- Electronically monitoring and displaying system service intervals.

- Flush function: Unidirectional or bi-directional, time selection: 10-60 min.

- Individual load cell for each oil vessel, to make higher accuracy of oil injection: ±1g.

- AC900 is for 1234yf refrigerant.

In Stock (will ship in 5-6 days).

- Automatic recovery/recycling/recharge, walk away and return when complete

- Automatic discharging used oil/oil drain.

- Automatic vacuum helps get to the necessary vacuum level in any condition quickly

- Automatic new oil injection shows how much oil was removed from the system during service

- Automatic internal tank refill. No stopping to fill the internal tank during service

- Automatic air purge removes the potential of air accumulating in the internal tank

- Comprehensive A/C capacity database

- Support Auto Mode: One step to do automatic recovery, recycling, vacuum and recharge

- Tank filling with manual or pre-set value options

- Onboard electronic scales

- Built in thermal printer

- Tank installed internally

- Vacuum leak test to identify gross leaks in a system

- Flashing feature

- Separate POE and PAG oil injection, good for service both electric/hybrid car and regular car

|

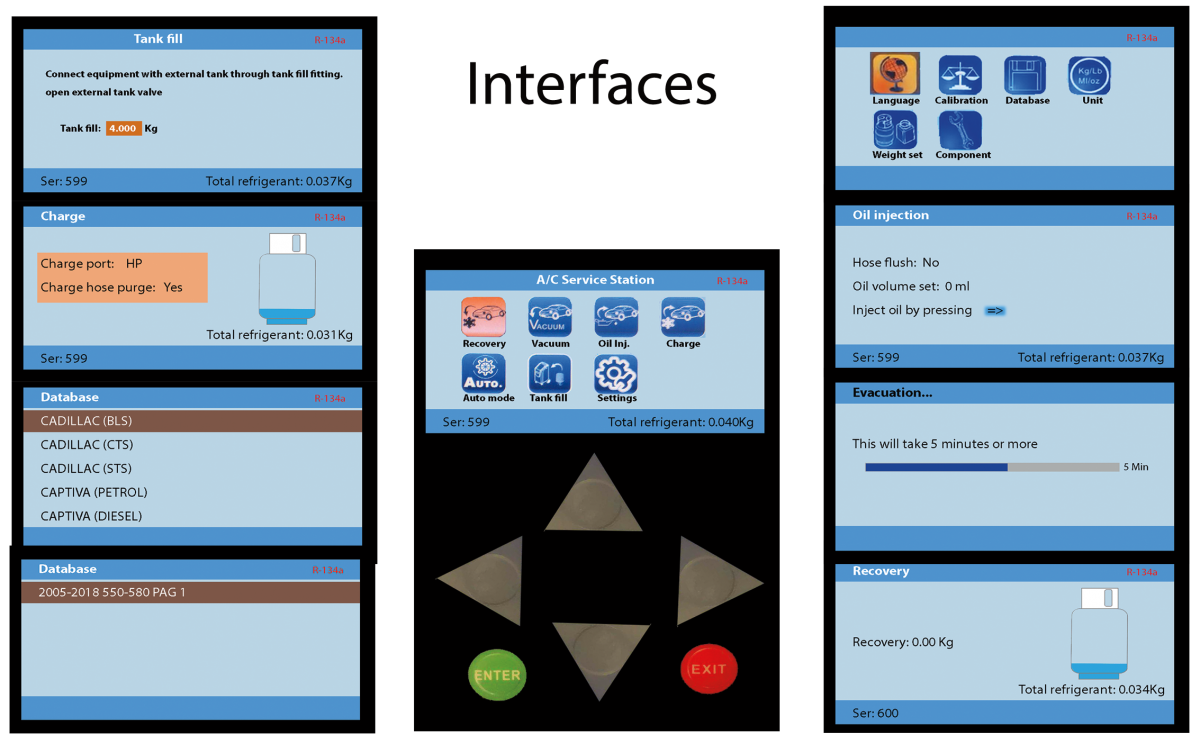

Main functions |

Recovery |

Recovers and purifies refrigerant from automotive A/C system and it is then stored into the machine internal storage cylinder for re-use. |

|

Evacuation |

Further removes air, debris, and moisture from the vehicle A/C system after recovery, with vacuum leak detection test. |

|

|

Charging |

Electronically charges the selected amount of refrigerant into the vehicle A/C system |

|

|

Oil/dye injection |

Electronically injects the pre-set or selected amount of oil and/or dye into the vehicle A/C system. |

|

|

Tank fill |

Transfers liquid refrigerant from an external cylinder to the machine internal storage cylinder. |

|

|

Flushing |

With this unique patented COR system, the machine will completely recover compressor oil, with which moisture and foreign particles are also recovered from the vehicle A/C system. When the technician selects forward flushing, the machine will pump high temperature and high-pressure refrigerant to A/C system in the direction of normal refrigerant flow (the refrigerant flows from the vehicle compressor low side and is recovered back from the high side during its cycle) or bi-directional flushing (refrigerant flows in both forward and reverse directions). All compressor oil in the vehicle A/C system and foreign particles can be extracted, and then discharged into the used oil vessel. |

|

|

Fully automatic function selection |

The machine will perform all the selected functions in a fully automatic sequence. The machine will stop automatically once all the selected functions or functions have been completed. |

|

|

System. settings |

Language |

Selecting language to suit. |

|

Calibration |

Calibrate refrigerant cylinder load cell, oil vessels load cells, pressure transducer, and temperature sensor. A dynamic password is needed to perform this function. |

|

|

Electronic air purge |

Purges any non-condensable from refrigerant storage cylinder. The machine also performs automatic non-condensable each time it is switched on. |

|

|

Vehicle database |

The machine stores a large number of vehicle makes and models, of the manufacturer recommended refrigerant and oil charge quantities, additional data can be added manually by the technician. |

|

|

Operating record |

The machine records and stores the operations the machine has performed; this data can be retrieved and also can be transferred to text file. A dynamic password is needed to perform this function. |

|

|

Unit settings |

Selecting metric or imperial units of measurement. |

|

|

Tare weight setting |

Set empty refrigerant cylinder or refrigeration oil zero (tare) weight. |

|

|

Component test |

Activate or des-activate each electronic component to make help analyze work status. A dynamic password is needed to perform this function. |

|

|

|

|

Download User Manual