- Input power:AC110V 60Hz.

- Compressor:3/8 HP.

- Vacuum pump capacity:16Gal/min.

- Recovery rate:99% to medium vacuum.

- Vapor state refrigerant recovery speed:0.55Lbs/Min.

- Gas cylinder volume:22LBS

- Drying filter:20oz

- Load cell accuracy(oil bottle):+_5g

- Load cell accuracy(gas cylinder):+_10g

- New and old oil bottle capacity:8.9/13.5oz Max working pressure 290PSI

- Color screen:4.3inch 480RGB*272Dots.

- Dimension:560*625*1048mm.

- One year warranty, two years part and three years compressor

SKU:

BDE-019-600 Price:

$4,995.00

In Stock (will ship in 1-2 business days).

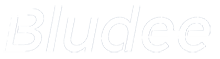

The model AC600 is featuring 95% recovery efficiency for standard and hybrid vehicles and fully automatic function or manual mode.

The AC600 machine recover, recycle, evacuate, leak-test and recharge 1234yf. It has automatic refrigerant refill and oil drain/inject – putting A/C lubricant back into the system. AC600 also builtin thermal printer and capacity database is available for all passenger vehicles.

- Automatic recovery/recycling/recharge, walk away and return when complete

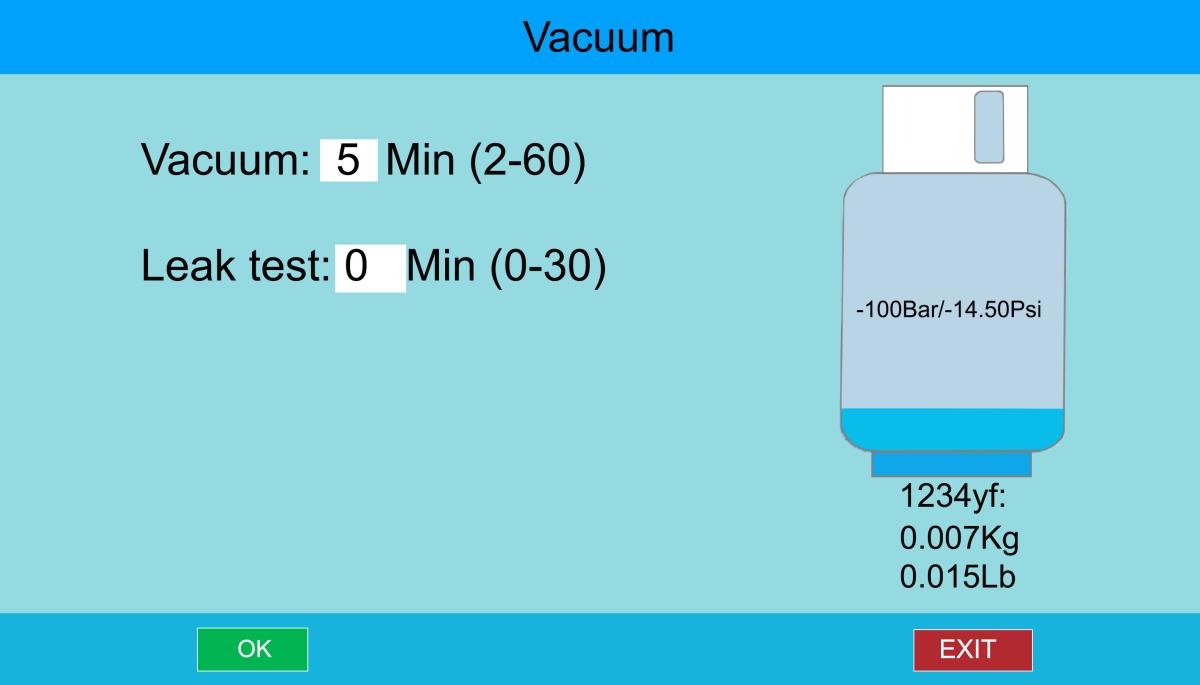

- Automatic vacuum helps get to the necessary vacuum level in any condition quickly

- Automatic air purge removes the potential of air accumulating in the internal tank

- Comprehensive A/C capacity database

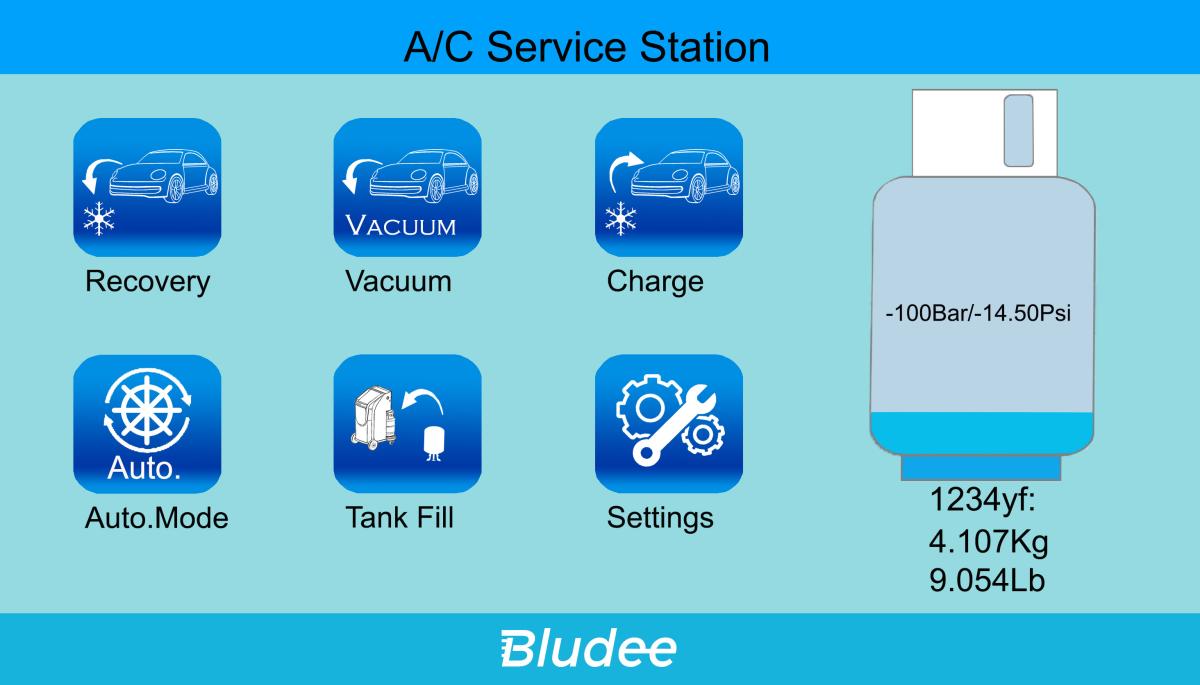

- Support Auto Mode: One step to do automatic recovery, recycling, vacuum and recharge

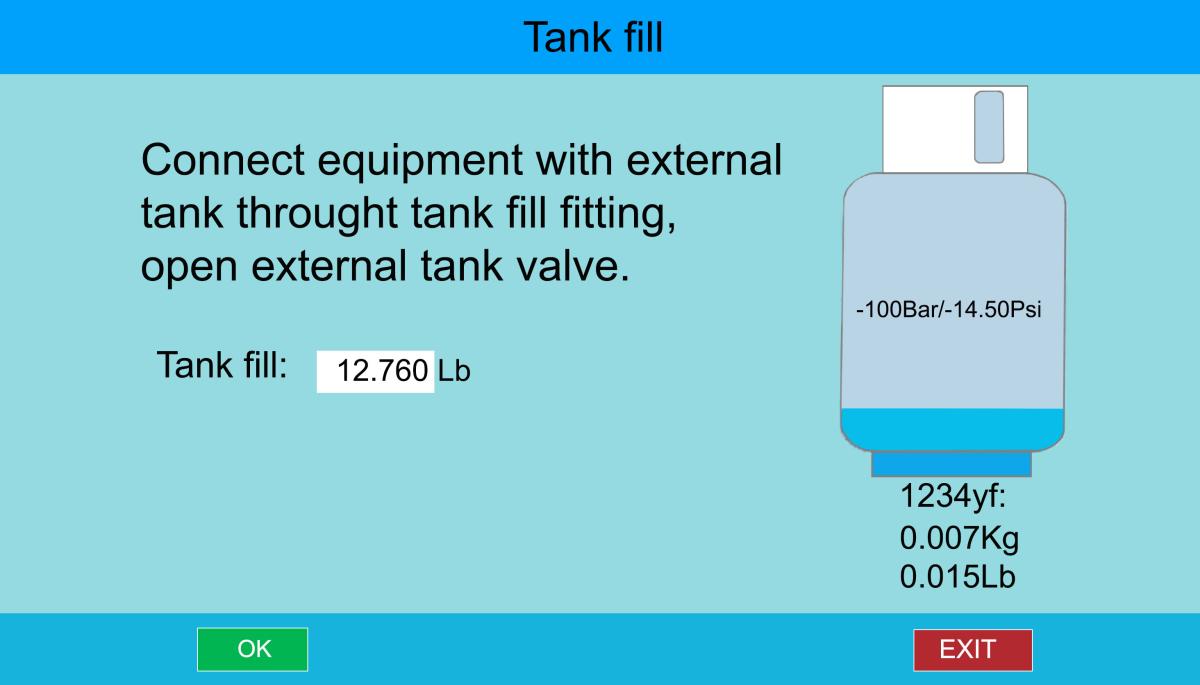

- Tank filling with manual or pre-set value options

- Onboard electronic scales

- Built in thermal printer

- Tank installed internally

- Vacuum leak test to identify gross leaks in a system

- Main functions

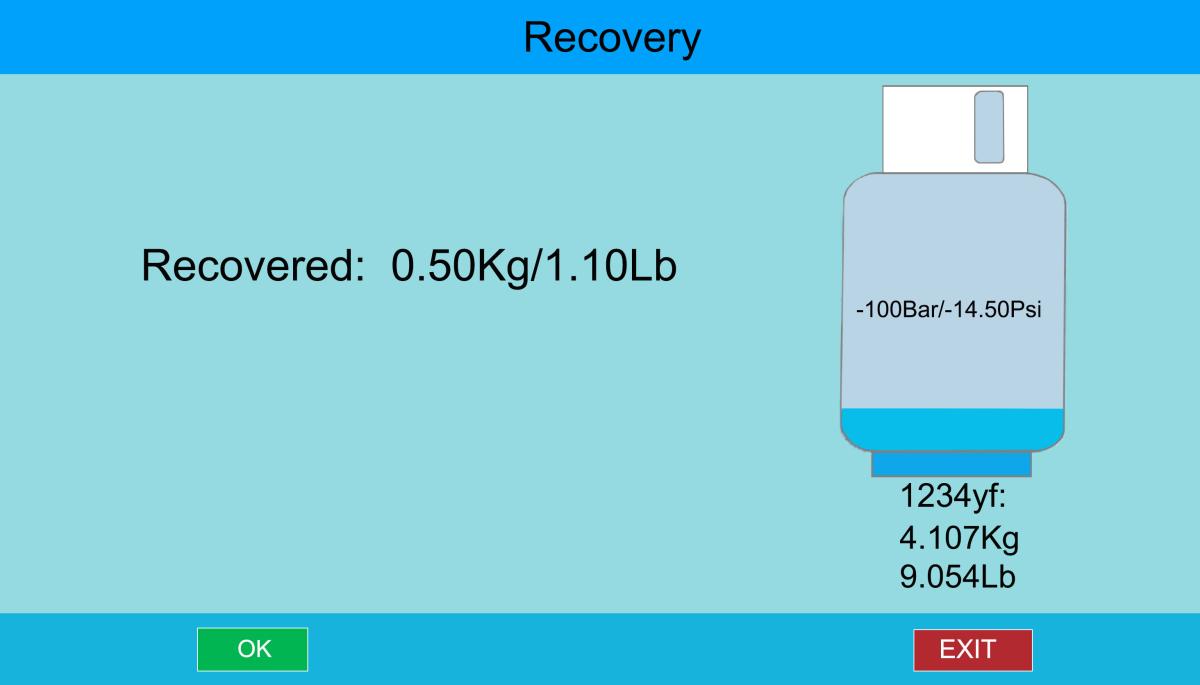

- Recovering/Recycling

- Discharging used oil

- Vacuum

- Refilling new oil

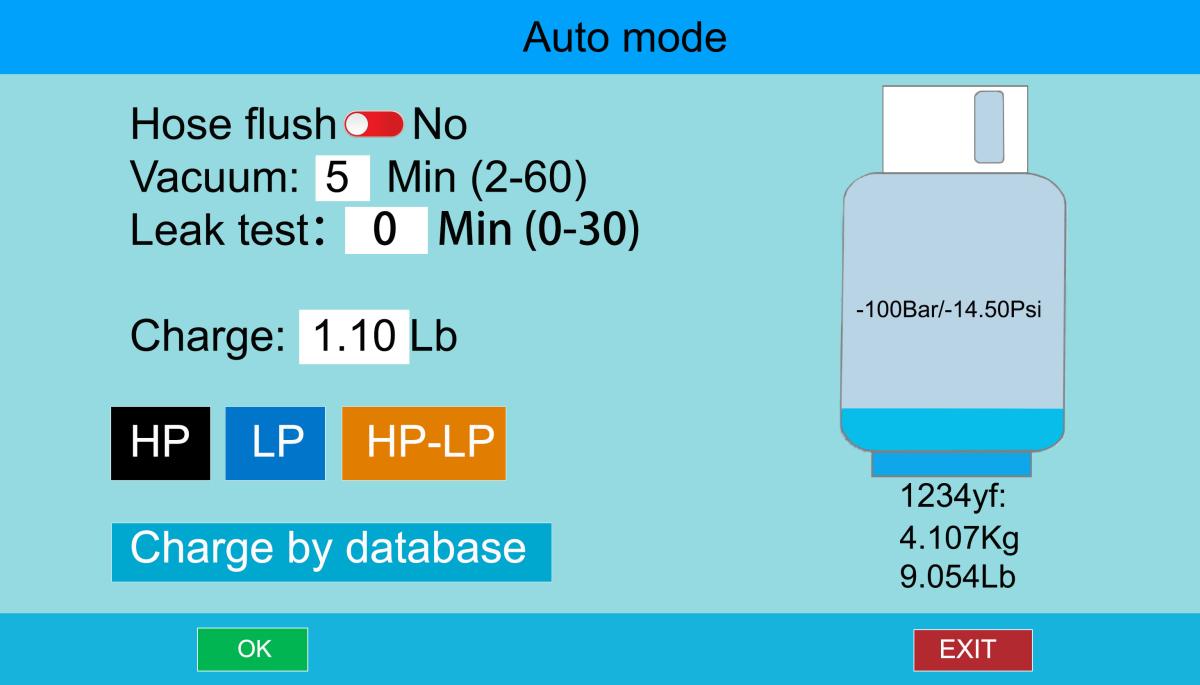

- Recharging

- Full Automatic mode

- Vacuum leak test (optional)

- Auxiliary functions

- Vacuum system piping

- Multiple alarms

- Maintenance procedures

- Part inspections

- Calibration of load cell

- Parameters setting

- Gas cylinder heating

- Incompressible gases discharging

|

|

|

|

Download User Manual